Quality Management

-

1.raw material control:

Supplier Selection: Select formal and competent suppliers to ensure the availability of lithium battery raw materials, timely delivery, and the reliability of material quality.

Raw Material Quality Inspection: Conduct rigorous incoming inspection for all raw material batches, covering electrodes, electrolyte, diaphragm, shell, etc. Ensure chemical analysis, appearance check, physical testing, and obtain quality documents from suppliers to meet international standards.

Storage And Management of Raw Materials: Proper storage and management of electrodes, electrolyte, diaphragm, shell, etc. Maintain dry, clean, odor-free conditions. Control shelf life to prevent quality deterioration.

-

2.the production process and process control:

Cleaning & Sterilizing: Equipment, tools cleaned & sterilized. Clean, hygienic env. with static protection;

Grinding & Mixing: Electrode materials ground & mixed for homogeneity;

Electrode Prep: Careful mixing, coating, rolling, cutting controls ensure quality;

Electrode Assembly: Precise stacking, winding, injection, encapsulation;

Gas Treatment: Minimize impurities, sterilize air to prevent contamination;

Prod. Conditions Control: Strict temp, humidity, gas flow controls for stability.

-

3.process quality inspection and testing:

In the lithium battery production process, it is necessary to utilize a range of analytical testing solutions to monitor the quality of materials, including vacuum drying to eliminate impurities in electrode films, assessing coating thickness and roll density during production, and conducting post-welding shell inspections to identify bursting points, pinholes, craters, and other defects.

-

4.finished product inspection:

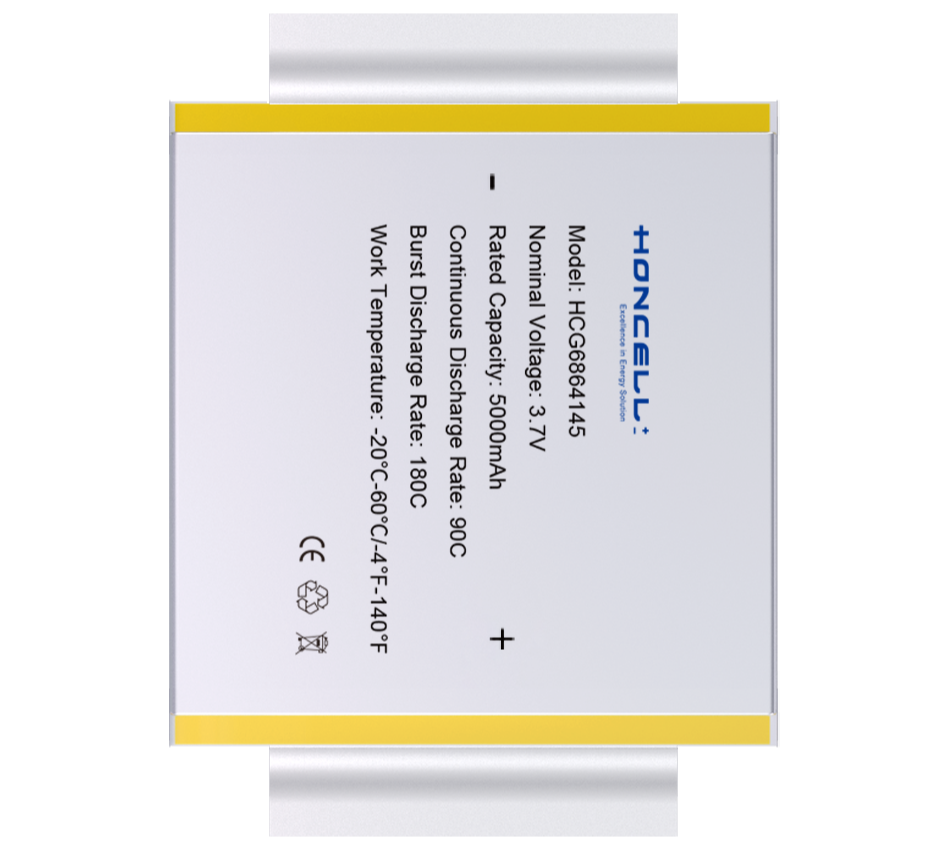

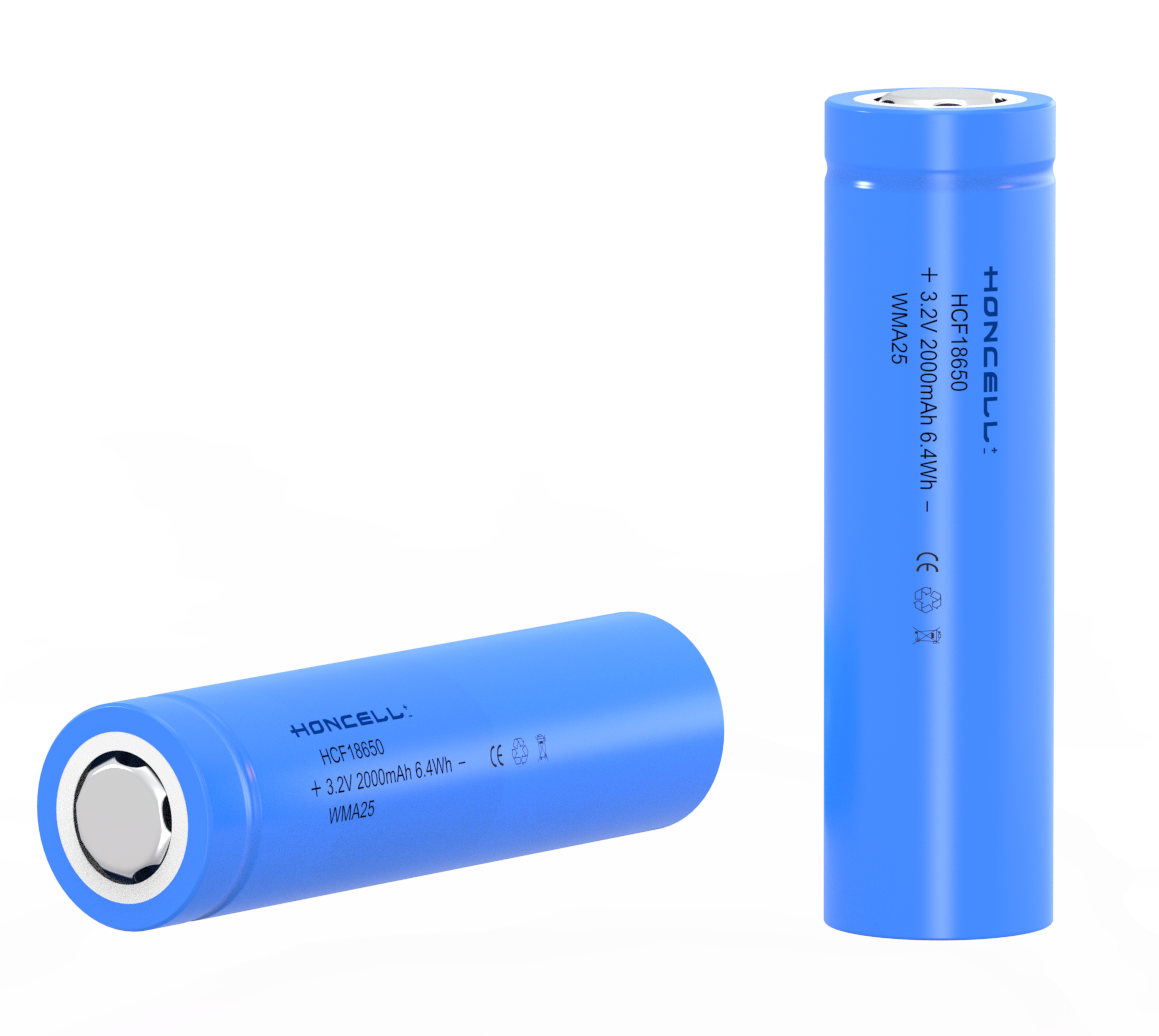

Morphological inspection: check for appearance defects, such as: battery dents, scratches, deformation, breakage, etc. and product size measurement.

Safety test: including over-charging, over-discharging, short-circuit, pin-point, extrusion, thermal shock and other tests, to ensure that lithium batteries will not occur in the process of use of hidden safety hazards.

Electrical performance test: including open circuit voltage, discharge capacity, discharge rate, self-discharge rate, cycle life and other aspects of the performance test, to ensure that the performance of lithium batteries meet the required standards.

-

5.Data recording and tracking:

Based on quality management, we realize the whole chain data pull-through and digital management of the quality process, and enhance the quality key indexes of the production process through statistical process control SPC and yield management.

-

6.personnel training:

Personnel, including production staff, technicians, purchasing staff, and management personnel, are key factors in determining the quality of lithium batteries. Regular quality management training for these personnel ensures that every link in the production process is in line with quality standards.

-

7.Environmental and safety control:

Lithium battery production process must comply with safety standards related to mechanical equipment safety, material and process safety, employee safety and health, and environmental protection, such as SJ/T 11798-2022 "Safety Requirements for the Production of Lithium-ion Batteries and Battery Packs". In addition, it is also necessary to prevent fire and explosion accidents to ensure the safety of the production environment.

-

8. lithium battery safety assessment and certification:

Physical (1.2m drop test, impact test), electrochemical (cyclic voltammetry test, electrochemical impedance spectroscopy test), electronic stability assessment (short-circuit test, overcharge test, discharge test) and thermodynamic properties (high temperature, low temperature) of lithium batteries are tested and analyzed to assess their safety in the process of use. At the same time, we certify lithium batteries that meet the safety requirements to ensure that they meet the requirements of international EC 62133 certification, UL certification, CE certification and other certifications and industry standards.