How to choose lithium battery customized manufacturers

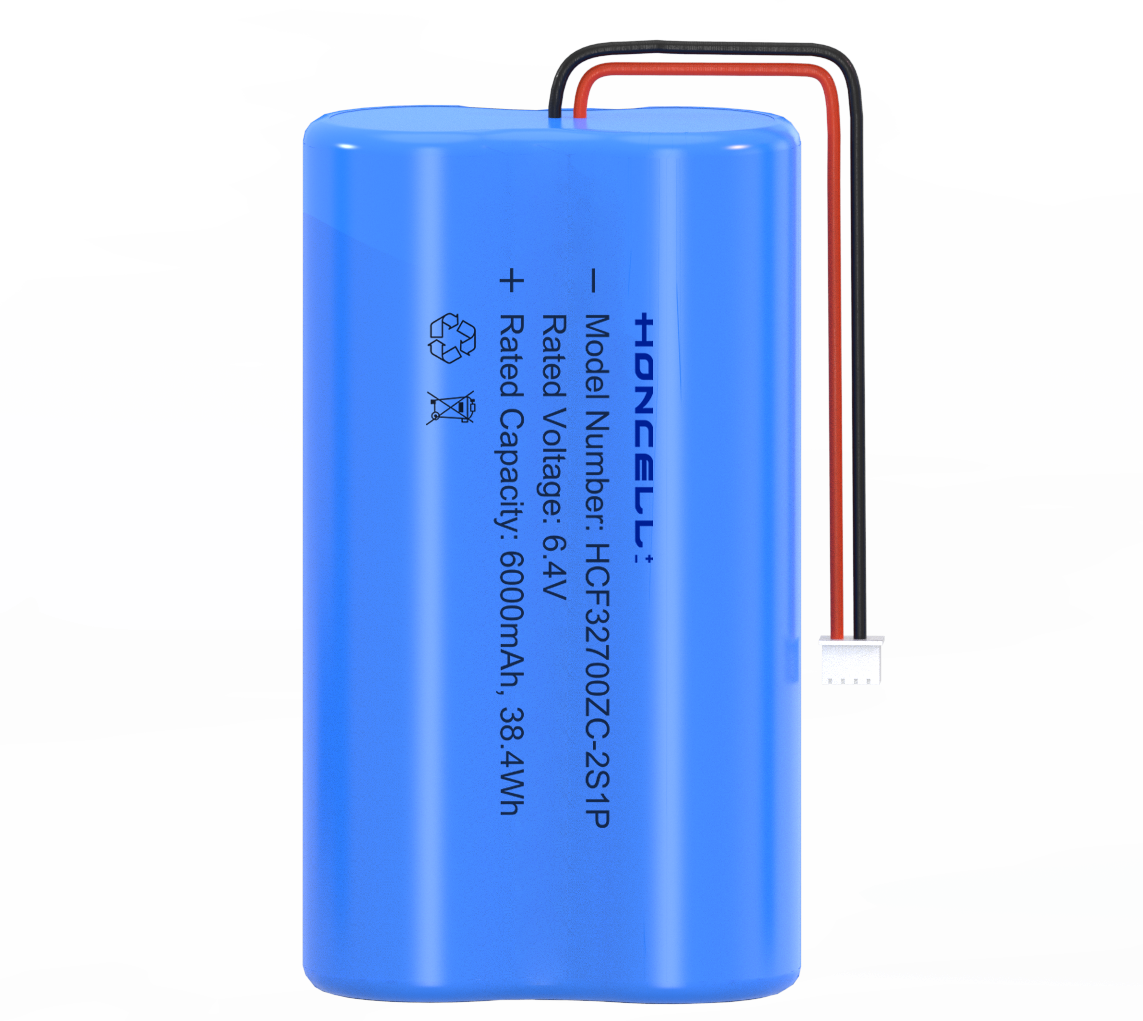

When the conventional battery can not meet the product demand, enterprises need to customize the battery, in the selection of lithium battery custom manufacturers need to consider product quality, production capacity, technical support, after-sales service and cost-effective and other factors to ensure the smooth delivery of the product. Therefore, through detailed research and evaluation, you need to select a reliable, in line with the needs of the customized lithium battery manufacturers. Honcell provides you with nine recommendations for selecting customized lithium battery manufacturers:

1, clear lithium battery needs

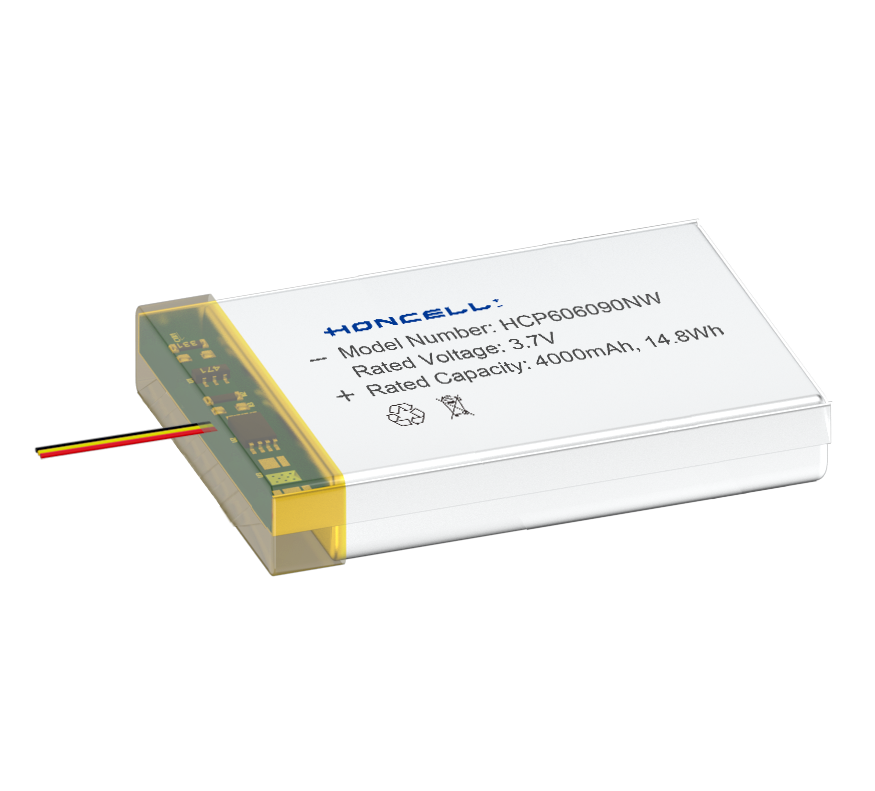

Need to be clear within the enterprise customized lithium battery application scenarios, product specifications, materials and other requirements. Specific needs are: battery capacity range, voltage, size size (length, style, thickness), multiplier, high and low temperature range, impedance, weight range, cycle life, and safety requirements;

Part of the enterprise, in the start-up period, may not be very clear about the needs of the battery, the need to set up a project team with custom manufacturers, according to the actual situation of the product application scenarios, the two sides to discuss and communicate with, customize the most suitable battery.

2, the strength of manufacturers

In the world, battery manufacturers are very many, the size of the scale varies greatly, you need to choose carefully. First understand the manufacturer's business license, the number of years of establishment, production license, size and so on. Whether the factory has passed ISO 9001 quality management system certification, ISO 14001 environmental management system certification. Whether its battery has passed the safety and performance certification, such as IEC, UL, CE, RoHS, UN38.3, Battery Directive, PSE, KC, CQC and other qualifications.

3, Production capacity

To determine the number of lithium batteries that need to be customized, if the demand is relatively large and urgent, it is necessary to find factories with large-scale production capacity and do not need to wait for production scheduling. Therefore, it is very necessary to understand the manufacturer's production capacity, scale, production process and technology, technical equipment, R & D capabilities, production scheduling, communication timeliness and so on.

4, Quality control

The quality of the battery is related to the safety of the product, the battery is very important. Quality control is the most critical factor in whether the battery is qualified, therefore, it is necessary to understand whether the manufacturer has a perfect quality management system, whether it can monitor the entire quality control from raw materials to finished products. At the same time, whether the battery manufacturer is equipped with advanced testing equipment and laboratories, which can be used to carry out battery cell testing, finished product testing, performance testing, safety testing, life testing and other tests.

5,price

Price is a factor that many purchases are most concerned about, and even decide whether to close the deal. The price of the battery is determined by a very large number of factors, such as: the number of customization, the capacity of the battery, the production cycle and many other factors to decide. In different factories, there may be relatively large price differences. Purchase price is one of the reference indicators, you also need to ensure the quality of the product and the cost of transportation, installation, maintenance, service and other costs. By comparing with multiple manufacturers, choose the most suitable manufacturer.

6, customer cases and corporate reputation reputation

Ask the manufacturer whether there are successful cases of similar projects, whether there is experience in cooperation with well-known brands, when it was completed, and who is responsible for it? At the same time, you also need to understand the manufacturer's corporate qualifications, credit rating, business status and reputation. If you can contact the manufacturer's customers directly, you can find out their real evaluation and feedback on the manufacturer.

7, after-sales service

After-sales service is the most critical part of a manufacturer's service system. Whether it can provide comprehensive technical support and training services to help solve technical problems related to batteries in the project; whether it has a comprehensive return policy, storage guidance, transportation safety, and security services – these are all important factors.

8, Field inspection

If you need to customize a larger number of lithium batteries, the production cycle is relatively long. Under permitted conditions, you need to visit the manufacturer's battery factory to directly observe the battery production environment, manufacturing process, management system, corporate culture, business philosophy, service concepts, and development planning. At the same time, face-to-face communication with the manufacturer's management, technical staff, service personnel, and production staff will provide an in-depth understanding of the company's level of professionalism, service awareness, and willingness to cooperate.

9, Sample test

Require manufacturers of lithium batteries to provide samples for testing. After the test, technical staff should assess the samples to ensure that the performance of the lithium batteries meets product requirements.

The more customized lithium batteries, the more detailed the preliminary research and evaluation needs, if you need to customize less, according to the actual situation of the company to determine the strength of the research (for example: whether the need for site visits). Eventually, through a comprehensive comparison, choose the most suitable manufacturer for customized production.

Related News

-

Nov. 2024How Drone Manufacturers Choose Lithium BatteriesLearn More

Nov. 2024How Drone Manufacturers Choose Lithium BatteriesLearn More -

Nov. 2024How medical device vendors choose lithium medical batteriesLearn More

Nov. 2024How medical device vendors choose lithium medical batteriesLearn More -

Sep. 2024Why global enterprises should choose Chinese lithium battery manufacturersLearn More

Sep. 2024Why global enterprises should choose Chinese lithium battery manufacturersLearn More -

May. 2024How to choose lithium battery customized manufacturersLearn More

May. 2024How to choose lithium battery customized manufacturersLearn More -

Mar. 2024How to wake up a dormant lithium battery and bring it back to performanceLearn More

Mar. 2024How to wake up a dormant lithium battery and bring it back to performanceLearn More -

Mar. 2024What should be considered when charging lithium batteriesLearn More

Mar. 2024What should be considered when charging lithium batteriesLearn More